Why Choosing The Right Equipment Is Critical For Industrial Job Success

Industrial projects demand steady planning, steady hands, and choices that support long-term performance. Every stage of a job site depends on tools and materials that hold up under pressure. When the wrong items reach the work area, timelines stretch, repairs rise, and crews lose momentum. Selecting equipment with care shapes safety, quality, and output. The discussion that follows looks at how dependable tools and materials influence results across a wide range of industrial settings.

Material Handling Starts With Chemical Stability

Many operations rely on compounds that interact with machinery, surfaces, and structural components. These materials guide curing, coating, bonding, and protection. The choices surrounding such supplies shape long-term durability. A single misstep with product type or grade increases wear, shortens service life, and introduces hazards. This becomes clear when teams look at options for treatments, hardeners, or sealants. Crews working in construction settings often turn to mixtures designed for strength and longevity, including concrete chemicals that support structural integrity through carefully balanced formulas. These mixtures work best when matched to project demands, storage conditions, and surface prep. Picking the right set of chemical products gives teams a cleaner application process and reduces the likelihood of premature breakdown.

Operational Flow Hinges on Proper Equipment Fit

Every industrial environment has its own rhythm driven by workflow design and the relationship between tasks and tools. When equipment aligns with daily demands, movement stays smooth and predictable. Machines operate with fewer pauses, and workers face fewer adjustments during shifts. A good fit also limits strain on key components, cutting down on downtime triggered by overheating, clogging, misalignment, or irregular vibration.

The search for a proper fit covers many categories. Power sources must match load requirements. Cutting tools must match surface hardness. Protective gear must match exposure risks. Even small choices, like the size of a connector or the torque range of a wrench, shape the consistency of an entire operation. Teams that pause to evaluate these relationships develop workflows that withstand heavy use, shifting weather, and unexpected surges in demand.

Key Points for Selecting Equipment

- Match the tool capacity with the daily workload to limit unnecessary strain on machinery

- Review environmental conditions that may affect performance, including humidity swings or high heat

- Choose suppliers with clear data on material grades, tolerance levels, and testing methods

- Evaluate compatibility across brands to avoid mismatched components

- Keep maintenance requirements in mind, so crews have clear expectations from the start

- Confirm that spare parts and service support are readily available before integrating new equipment

Cost Control Relies on Smart Equipment Investment

Budget overruns in industrial projects often trace back to repeated repairs, slowdowns, or idle time caused by inadequate tools. At first glance, cheaper options may help short-term cash flow. Once deployed, shortcomings reveal themselves through rapid wear or failure under heavy loads. This sets off a chain reaction of delays, emergency purchases, and rescheduling.

Smart investment strategies look past the upfront price tag. Long-term reliability, repair intervals, and compatibility with existing systems matter far more. Stronger materials, tighter tolerances, and proven performance in field conditions pay off through reduced downtime and smoother execution. Crews maintain steady progress, and managers gain confidence that schedules will hold. Money saved from fewer repairs and stoppages often outweighs any initial savings from bargain equipment.

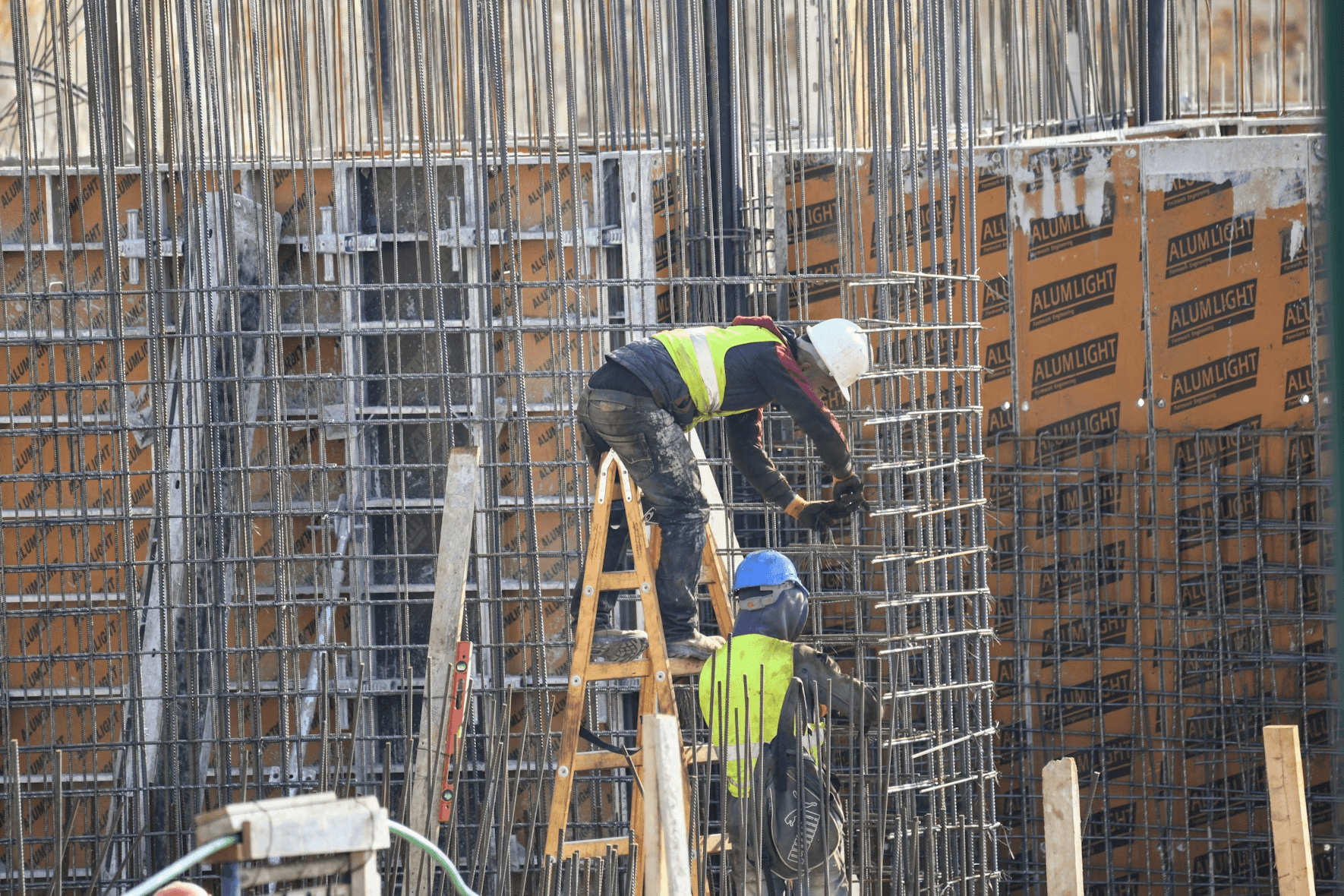

Safety Culture Depends on Reliable Tools and Machinery

Every industrial site carries its own set of risks. Moving parts, high loads, sharp edges, and elevated surfaces introduce hazards from the moment work begins. Reliable equipment helps lower these risks by offering consistent and predictable performance. When tools behave as expected, workers avoid sudden surprises like slipping blades, failed clamps, or motors that stall during critical moments.

Safe environments grow when teams trust their gear. Harnesses remain steady under tension. Lifting equipment moves at a steady pace without jolts. Sensors hold their calibration. Tools with dependable design protect workers from exposure to dust, loud noise, or high temperatures. Safety procedures gain strength when supported by tools that function the same way every day. Crews gain a sharper focus when they are not forced to compensate for failing or unpredictable equipment.

Long-term project Outcomes Improve With high-quality selections

Many industrial projects involve structures, systems, or products that must perform reliably for years or decades. The lifespan of an installation often mirrors the quality of the items used during assembly. Durable tools produce accurate cuts, clean welds, and steady alignments. Strong materials resist corrosion, deformation, and fatigue. Consistency at the build stage supports consistent performance long after crews leave the site.

The right selections also influence maintenance schedules. Items that stay within specification reduce the need for constant touch-ups or replacements. This protects budgets and limits interruptions for clients or building occupants. Industrial teams with a reputation for reliable outcomes often share a common pattern: they choose quality from the beginning. This practice supports stable progress, fewer callbacks, and solid client satisfaction.

Industrial success grows from choices made long before a job begins. Equipment selection affects workflow, safety practices, cost control, long-term durability, and the day-to-day confidence of every worker on site. When every piece of equipment supports the task at hand, industrial teams build stronger structures, finish projects with fewer delays, and stand behind results that last.